Hot Bonders

Hot Bonders

As industries rapidly grow in size and mature in terms of the techniques and technological breakthroughs leveraged, there is a growing need of a vigilant and fool-proof repair system, such as hot bonders, to ensure the integrity of complex structures.

It is not enough to detect wear and tear and breakage in time. The adhesives, hot bonders or resins used to initiate composite and metal bond repairs must be:

- Sturdy so that they can function properly in extreme climates

- Portable so that they can be carried into the tightest corners and smallest spaces without any issues

- Flexible – they should have multiple heat application tips and the ability to connect with other repair units to co-ordinate the temperature of curing for large and sprawling projects

The new-age hot bonders embody all these desirable characteristics. They prove to be invaluable for traditional bonding or repair assignments, secondary bonding processes that generally rely on ovens or autoclaves to proceed without hitches and for research and development projects where prototypes may need to be frequently assembled and dismantled and thus run the risk of compromise.

Bonders epitomize convenience and they have radically transformed the way delicate and precise repair work is conducted for commercial and technical endeavors.

WICHITECH INDUSTRIES INC. AND ITS RANGE OF CUTTING-EDGE HOT BONDERS:

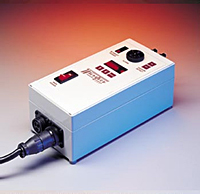

Laying claim to the prestigious epithet of the world’s hottest hot bonders, Wichitech’s line of HB1 and HB2 Composite units are fully manufactured in the US and at as little as 35 pounds they stand for light weight efficiency.

All components of the units are shock mounted in rugged, impact resistant cases that hold themselves well under extenuating circumstances. They come with easy to manipulate settings and a clear display to expedite curing and the exacting task of setting the right temperature for the bonding to be invulnerable.

SPECIALTIES OF THE HB1 BONDERS:

This fully featured unit is economical to say the least. It packs the punch of larger, more expensive set-ups and comes with multiple thermocouples, a fail-safe mechanism of triggering an alarm if conditions are not conducive to repair work and even a vacuum line and heat blanket to ensure complete lack of moisture and ambient temperature fluctuations which interfere with the sealing process.

This fully featured unit is economical to say the least. It packs the punch of larger, more expensive set-ups and comes with multiple thermocouples, a fail-safe mechanism of triggering an alarm if conditions are not conducive to repair work and even a vacuum line and heat blanket to ensure complete lack of moisture and ambient temperature fluctuations which interfere with the sealing process.

SPECIALTIES OF THE HB2 BONDERS:

One evolutionary step above the H1 units, the HB2 bonders possess all the differentiators that set its predecessor apart with a few key add-ons.

They have two independently programmed heating zones of 20A each to perform cures at different temperatures. A list of pre-programmed options in the menu obviates the need of expertise to use the unit optimally. Compact yet extremely powerful it renders everything from Kevlar to carbon to fiberglass pliant.

Wichitech Industries Inc. lives by the tenets of simplicity, affordability and quality. Its bonders have an impeccable reputation in the market and represent the best of the advancements made in this field.